Blockchain-Integrated IoT Device Revolutionizes Casting Defect Inspection

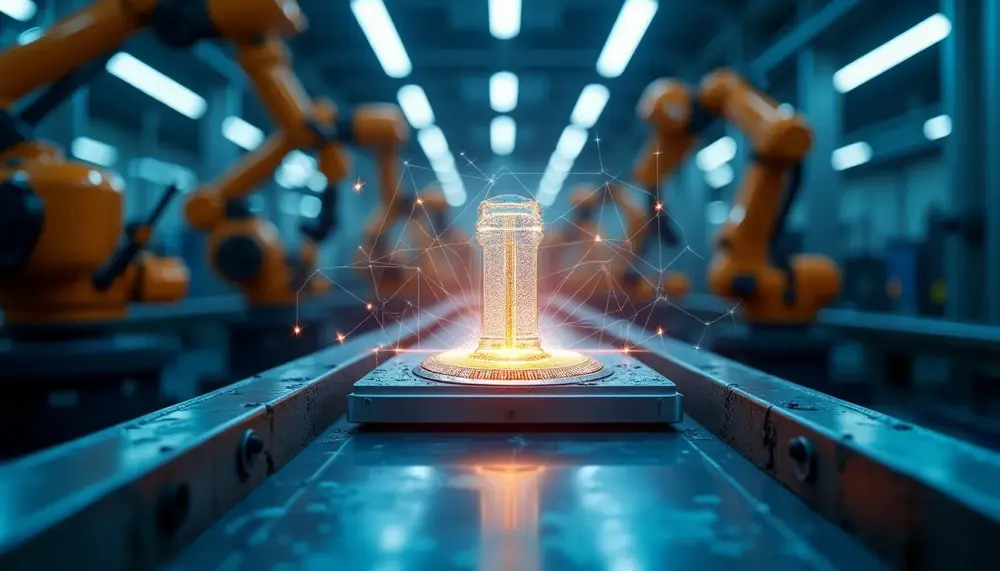

A groundbreaking study published on Nature.com titled "Blockchain-integrated IoT device for advanced inspection of casting defects" introduces a transformative approach to quality control in investment casting. The research, led by Nabhan Yousef and colleagues, highlights the integration of Blockchain technology with IoT devices and a ResNet-based deep learning model to address critical challenges in defect detection, data traceability, and operational efficiency. The system achieved an impressive F1-score of 0.94 for defect detection, with data integrity and traceability metrics reaching 0.99 and 0.98, respectively. Furthermore, the system processes each casting in an average of 2.3 seconds, enabling a throughput of 26 castings per minute. This innovation not only enhances manufacturing transparency but also ensures regulatory compliance and user confidence. For more details, visit the original article on Nature.com at https://www.nature.com/articles/s41598-025-86777-3.

The study emphasizes the limitations of traditional defect detection methods, such as manual inspections and isolated machine learning models, which often lack real-time processing and secure data management. By integrating IoT-enabled inspection systems with Blockchain, the proposed solution ensures immutable and traceable data storage, addressing issues of data tampering and enhancing operational transparency. The system's ability to combine real-time defect detection with secure data management makes it a pivotal advancement for Industry 4.0, particularly in sectors like automotive and construction where stringent quality control is essential.

The research also delves into the technical aspects of the system, including the use of a high-resolution camera for capturing detailed images of investment castings. These images undergo preprocessing steps such as noise reduction, contrast enhancement, and geometric adjustments to ensure accurate analysis. The ResNet-based deep learning model extracts features like texture patterns, contour shapes, and color variations to identify defects and measure dimensions with high precision. The dimensional measurement system demonstrated a mean absolute error of just 0.05 mm, showcasing its reliability for quality control in manufacturing.

Blockchain technology plays a crucial role in this system by securely storing inspection data, including defect classifications and dimensional measurements, in an immutable format. Transactions are validated using consensus mechanisms like Proof of Work or Proof of Stake, ensuring data integrity and preventing tampering. The system's real-time performance was tested, revealing its capability to handle 26 castings per minute, equating to 37,440 castings in a 24-hour period. Despite the computational demands of Blockchain, the benefits of enhanced security and traceability outweigh the costs, making this system a viable solution for modern manufacturing challenges.

While the study acknowledges areas for improvement, such as scalability and energy efficiency, it underscores the transformative potential of integrating IoT and Blockchain technologies. By addressing these challenges, the system paves the way for smarter, more transparent, and reliable manufacturing processes, setting a new standard for quality control in Industry 4.0. For a comprehensive understanding of this innovative approach, refer to the full article on Nature.com at https://www.nature.com/articles/s41598-025-86777-3.

Sources: